Green Waste Recycling

1,282,050 tonnes

of green waste recycled

793,350 tonnes

of CO2e emissions prevented

Over 500,000 tonnes

of compost produced

Composting is at the heart of what we do! Each year we receive and processes ~75,000 tonnes of green waste, from a variety of commercial and Local Authority customers, as well as local Landscapers & Arboriculturalists.

Since opening our gates, we’ve recycled over 1 million tonnes of green waste and produced well over 500,000 tonnes of high quality, PAS:100 certified, soil improving compost.

Whilst composting is natures very own circular process, we’ve perfecting it, on an industrial scale. By utilising the latest equipment and monitoring techniques by a team of commited and trained staff we give nature a helping hand, and esnure that the highest standards of integrity and control are maintained throughout the 12 week process.

Our range of Composts are marketed to a network of customers and garden centres and meet the standards of the most discerning horticulturists.

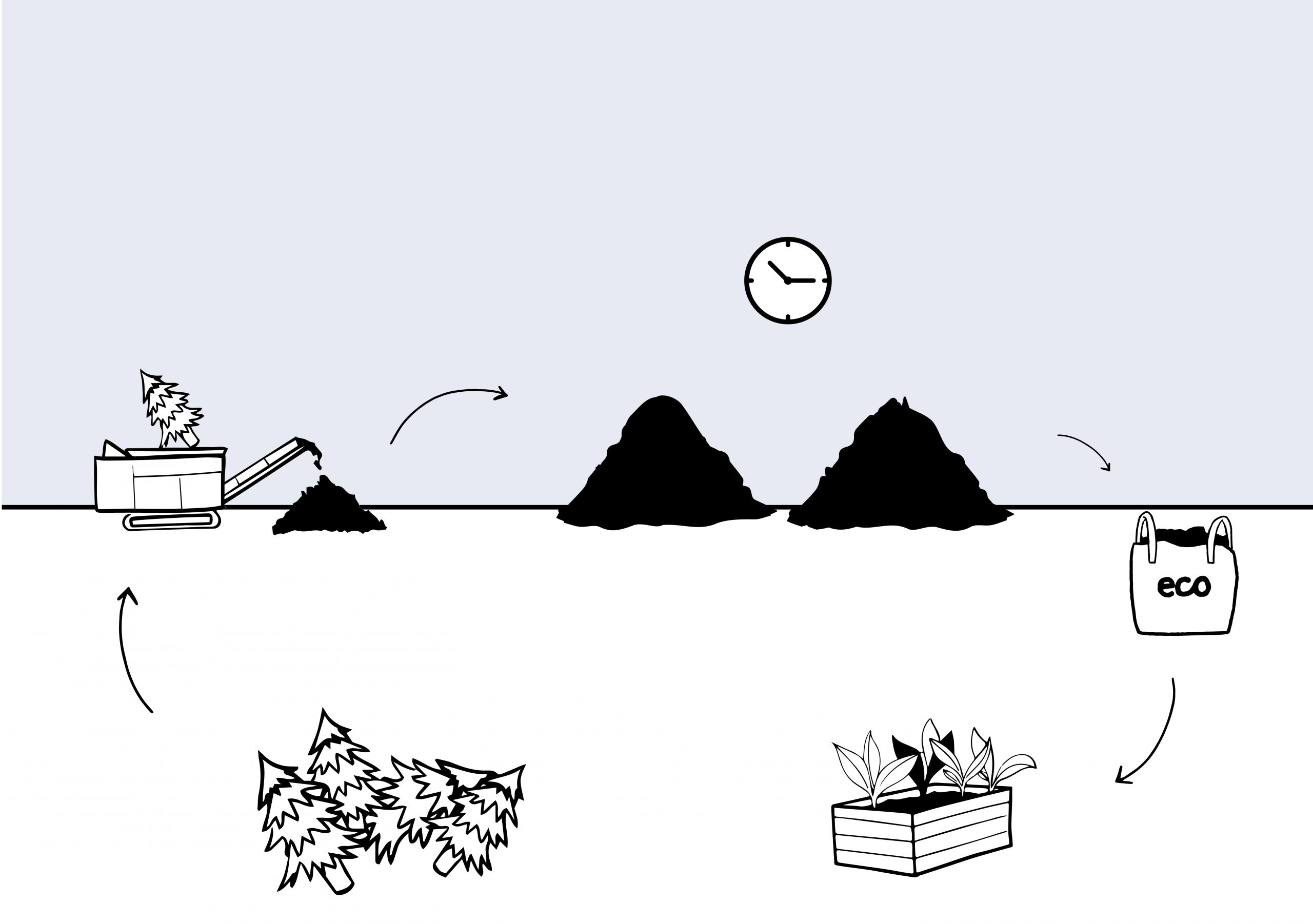

Process Steps:

- Garden Waste Disposal: From householders disposing garden cuttings at their local Recycling Centres and collected from green bins, or local landscapers depositing directly with us, most of the Dorset’s Green Waste is recycled by Eco.

- Shredding: Using electric shredders, powered by renewable energy, the garden waste is then processed into smaller, more homogeneous particles, before being stacked into huge, long batches called windrows.

- Open Windrow Composting: Once a windrow is formed, it is assigned a unique batch number and barcode. By keeping a close eye on the relationship between Oxygen, Carbon Dioxide, Heat and Moisture, we are able to create and maintain the optimum environment which allows the bugs to break down the material to create the perfect compost, whilst meeting all compliance demands.

- Product Preparation: After a 8-12 week composting and maturation period, the material is ready to be processed into its final products. This involves removing any left-over contamination, before being expertly size-graded through bespoke screening equipment, to produce our range of quality soil improvers and growing media.

- Quality Outputs: We manufacture a range of composts for the horticulture, landscaping, and agricultural industries. With slow-release nutrients, compost provides a natural enhancement to soil, as well as an abundance of organic carbon.

With up to 20% of the input ending up as ‘oversize’ material, Eco has invested in sophisticated drying and separation facility to produce a biomass fuel suitable for energy plants, displacing virgin alternatives by converting a waste into a resource.