Callow Hill

Anaerobic Digestion Facility

Who is Eco Sustainable Solutions?

Eco is a family run company specialising in Waste & Renewable Energy. Since Eco was founded in 1995, we’ve recycled over 4.3 million tonnes of organic material, preventing over 2 million tonnes of CO2e from being emitted to the atmosphere – that’s the equivalent to over quarter of a million return flights to Australia!

Over the past 30 years, Eco has led a variety of sustainable projects from organic waste recycling, producing green power from food waste to developing, at the time, the largest Solar Farm in Europe.

Eco currently recycles over 250,000 tonnes of organic material each year, converting it into renewable energy or high-quality landscaping products, like certified composts, mulch, and nutrient rich topsoil.

From sustainably leading the way in the development and implementation of renewable energy solutions, to our passionate team constantly challenging themselves to make processes more carbon efficient, we will continue to fight climate change by constantly striving to be Always More Sustainable

What is Anaerobic Digestion?

Anaerobic Digestion (AD) takes place when biodegradable material is broken down by microorganisms in the absence of oxygen. During this process, these organic materials are converted to biogas.

A biogas can be created from food waste, which would have previously been disposed of through landfill.

The biogas is then upgraded into biomethane and injected into the UK’s national gas network. Biomethane production helps the UK reduce its dependence on imported gas, while also cutting greenhouse gas emissions, when compared to natural gas.

Once all the biogas has been extracted from the food soup, the food soup is pasteurised and spread on local farms as a natural bio-fertiliser.

Environmental Benefits of Treating Food Waste by Anaerobic Digestion:

Reduction in Greenhouse Gas Emissions

Food waste in landfill breaks down anaerobically and releases methane — a greenhouse gas 28x more potent than CO2. Diverting food waste to Anaerobic Digestion significantly reduces these emissions, contributing to the UK’s Net Zero by 2050 goals.

Increased Resource Recovery

Instead of being lost to landfill or incineration, food waste is transformed into renewable energy (biogas) and bio-fertiliser (digestate). This supports a circular economy, where waste is reused productively.

Reduced Reliance on Fossil Fuels

Biogas produced from food waste can replace natural gas in homes and diesel in HGVs, cutting carbon and improving air quality.

Why Build a New Anaerobic Digestion Plant Here & Now?

This new legislation mandates separate weekly food waste collections for all UK households by March 2026 and all commercial premises by March 2025, unless the premises produce less than 5kg per week.

Currently, Wiltshire Council does not offer universal weekly food waste collections, so must introduce a compliant scheme prior to an agreed deadline of August 2027.

Callow Hill AD will offer an in-county solution to positively treat this additional food waste and convert it into renewable energy in the form of biomethane.

Park Grounds Waste Facility is an effective waste management facility, which has been in operation for over 30 years. It is allocated in the adopted Waste Local Plan as a site suitable for treating food waste.

Is the site actually earmarked by the Council for waste uses?

Yes. Park Grounds Farm (the wider site that includes Callow Hill AD) is an allocated waste site in the Wiltshire & Swindon Waste Site Allocations Local Plan (Adopted Feb 2013).

The Plan lists “Landfill/landraise extension and Waste Treatment” as the potential uses at Table 2.6 – Park Grounds Farm, identifying it as a strategic site. The entry also notes the B4042 access, nearby M4/rail corridor and the existing waste operations already present on the site.

How does the site fit with local waste policy?

The allocation is intended to help deliver the Waste Core Strategy’s capacity needs and is consistent with policies WCS1, WCS2 and WCS3 (strategic locations for waste development close to key settlements).

In short: this is one of the places the Councils expect new waste treatment capacity to come forward.

Is this a brand-new industrial location?

No. The wider Park Grounds site has hosted waste operations for decades (landraise/landfill, recycling/composting). The Local Plan explicitly describes it as an existing waste management facility and safeguards it for continued waste uses, so development here consolidates activity on an established site rather than dispersing it elsewhere.

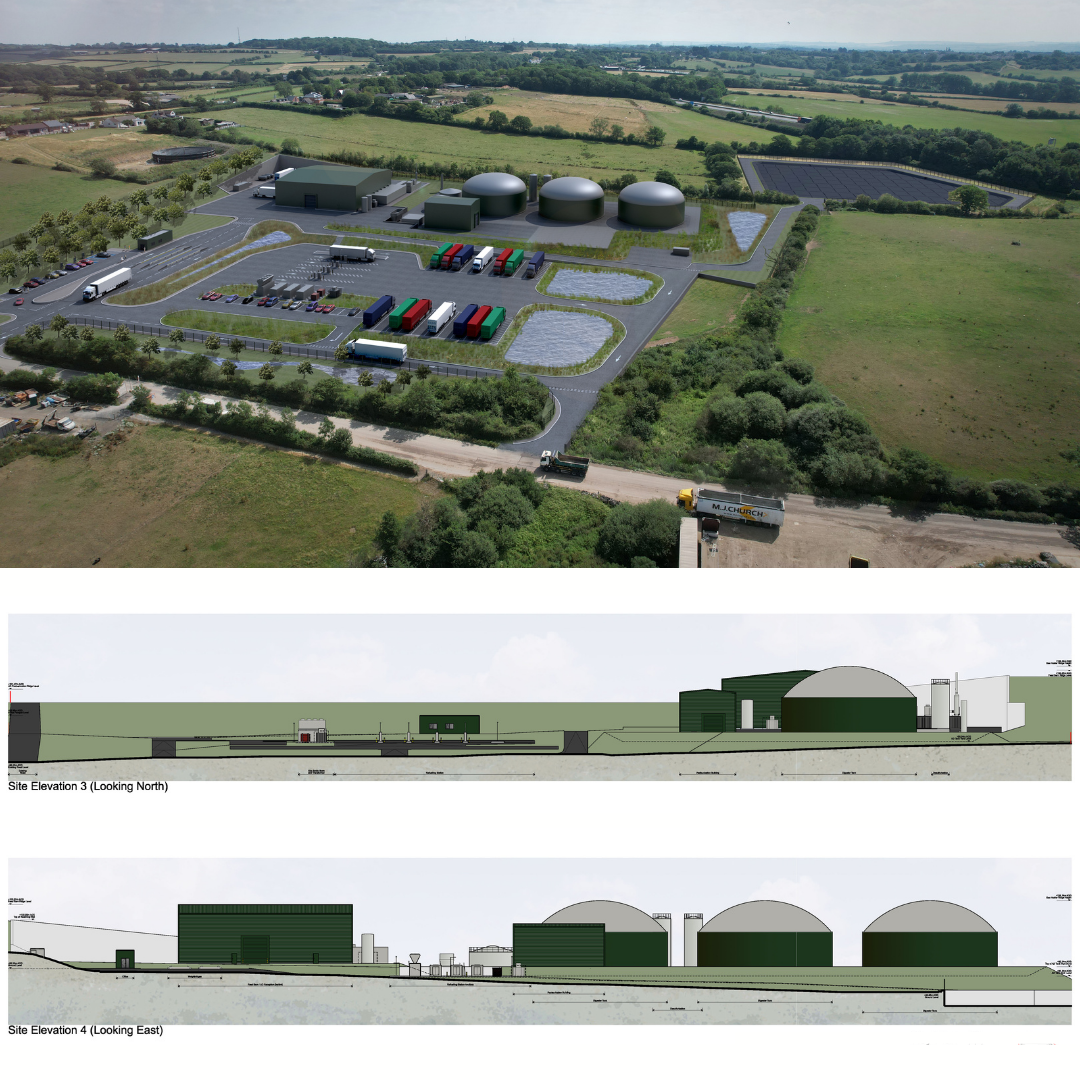

The overall site would be around six hectares and would be naturally screened around its perimeter by trees and natural fall of the land. The site is split into two distinct, but connected areas, an Anaerobic Digestion (AD) Facility and a HGV Refuelling Depot.

The AD facility will contain a reception barn which would receive and pre-treat the food waste to create a food soup. The facility would have five tanks comprised of three domed-roof digesters and two pre-storage tanks.

The gas from the digestors is captured within the domes before being refined and upgraded. The upgraded biomethane will be utilised as a renewable fuel for HGV’s at the onsite refuelling depot, or transported through a dedicated pipe to the gas network and used to heat local homes.

The food soup is pasteurised on site to form a nutrient-rich bio-fertiliser which will be used by local farmers to support sustainable crop production.

A fully covered and sealed lagoon will be utilised to store the bio-fertiliser ready for collection by local farmers.

Eco would be using the same technology it has applied at their two existing sites in Dorset. Plans for this plant includes the ability to capture the naturally occurring by-product, CO2.

The plant is able to prepare the CO2 to be transported away from site and permanently stored in either geological formations or embedded in long-lasting products like concrete. This process is called Bioenergy with Carbon Capture and Storage (BECCS).

The HGV Refuelling Depot will dispense Bio-CNG, which is compressed bio-methane, directly from the AD facility. Bio-CNG offers huge greenhouse gas savings compared to diesel.

The facility will benefit from three dispensers which can be utilised by heavy good vehicles (HGV’s) that are depositing food waste at the AD facility, and adjacent waste management facility.

34,000,000 kWh

of biomethane (enough to heat over 2,950 homes)

62,000 tonnes

of bio-fertiliser

7,000> tonnes

of CO2 savings per year

Environmental Gains

Diverts 75,000 tonnes of local food waste from going to landfill each year

Reduces over 7,000 tonnes CO2e emissions annually

Replaces fossil fuels in homes and HGV’s with a renewable solution

Produces nutrient-rich bio-fertiliser to replace fossil alternatives in local agriculture

Aligns with multiple UN Sustainability Development Goals, including clean energy, responsible consumption, and climate action

Community Benefits

Creates 6-8 permanent jobs, plus opportunities in construction, transport, and operations

Provides a local supply of bio-fertiliser to nearby farms

Supports the councils recycling goals

Energy security through on-site generation of renewable power

Local community fund to support good causes

FAQs

What is being proposed?

An anaerobic digestion facility at Park Grounds, Wootton Bassett that will treat up to 75,000 tonnes of food waste annually, producing renewable biomethane and organic fertiliser.

Why is this facility needed

New UK laws (Simpler Recycling) require separate food waste collections from all households by 2026. Wiltshire needs local infrastructure to treat its food waste sustainably and avoid long-distance transport or landfill.

Who is behind the project?

Eco Sustainable Solutions Ltd and Crapper & Sons Waste Management. Both are family run businesses with over 30 years experience in effectively managing waste and creating pioneering environmental solutions.

What are the benefits?

- 25 million kWh of renewable gas/year

- Over 7,000 tonnes of CO2e savings

- Heat for 5,000+ homes or fuel for 80 HGV’s

- Nutrient-rich bio-fertiliser for local farms

- Local employment and investment

What will the site look like?

What is Biomethane?

What is Bio-CNG Refuelling?

When will it be operational?

Subject to planning approval, construction would begin in 2026 and the site would become operational in Q4 2027 in time for the mandated Wiltshire residents food waste collections.

Why Here

Is the site actually earmarked by the Council for waste uses?

Yes. Park Grounds Farm (the wider site that includes Callow Hill AD) is an allocated waste site in the Wiltshire & Swindon Waste Site Allocations Local Plan (Adopted Feb 2013).

The Plan lists “Landfill/landraise extension and Waste Treatment” as the potential uses at Table 2.6 – Park Grounds Farm, identifying it as a strategic site. The entry also notes the B4042 access, nearby M4/rail corridor and the existing waste operations already present on the site.

How does the site fit with local waste policy?

The allocation is intended to help deliver the Waste Core Strategy’s capacity needs and is consistent with policies WCS1, WCS2 and WCS3 (strategic locations for waste development close to key settlements).

In short: this is one of the places the Councils expect new waste treatment capacity to come forward.

Is this a brand-new industrial location?

No. The wider Park Grounds site has hosted waste operations for decades (landraise/landfill, recycling/composting). The Local Plan explicitly describes it as an existing waste management facility and safeguards it for continued waste uses, so development here consolidates activity on an established site rather than dispersing it elsewhere.

Traffic

Will the site cause extra traffic on local roads?

The Anaerobic Digestion plant will generate around 42 vehicle movements per day on average, with a maximum of 105 two-way movements on the busiest days.

To put this in context, the B4042 currently carries over 5,400 vehicles per day. The additional traffic from the facility would therefore be less than 2% of daily flows, a change that is considered negligible and unlikely to be noticed day-to-day.

Vehicles will only operate during set delivery hours (07:00–19:00 weekdays, 07:00–15:00 Saturdays), with no HGV movements at night. A lorry routing agreement ensures that HGVs use designated main roads, avoiding unsuitable local routes.

What about impacts on the motorway junction (M4 J16)?

Even assuming all site traffic travelled via Junction 16 (a worst-case scenario), this would add just 0.3% to daily traffic flows at the junction. This is well within normal day-to-day variation and has been confirmed as having no material impact on congestion or safety.

Will construction traffic be a problem?

Construction will last 12–18 months and will be managed under a Construction Traffic Management Plan (CTMP). This sets clear rules for delivery times, access routes, and wheel-washing to minimise disturbance.

Construction hours are restricted to 07:00–19:00 Monday–Friday and 07:00–15:00 Saturdays, with no noisy works outside these times.

How safe is the site access?

The site entrance has been used by HGVs since the 1980s. Visibility is excellent, and no accidents have been recorded at the access in the last five years. Swept path analysis confirms that large vehicles can enter and exit safely without affecting other road users.

Visual Impact

Will the site be visible from nearby homes and footpaths?

The site is in a low-lying position, surrounded by existing woodland and hedgerows. A detailed visual study looked at views from over 1.5 km around the site, including local footpaths and nearby villages.

In most cases, existing trees and landform screen the development completely. Where parts of the facility could be seen, views are partial and filtered through hedgerows, and in the context of the existing Crapper & Sons site nearby.

What about views from the B4042 and local roads?

From the B4042, the facility would be mostly screened by hedgerows and roadside vegetation. From Brinkworth Road, only limited glimpses may be possible at the site entrance. The overall effect is assessed as slight to negligible.

Will people on local footpaths see the site?

A series of photomontages were prepared from key public footpaths (PRoW). These show that:

- At 560m from the site, vegetation provides strong screening.

- At 1.3km away, the facility is seen only in the distance alongside other farm and industrial buildings.

- Even at the closest path (415m), views are filtered and softened by hedgerows.

Overall, effects on walkers and residents are assessed as minor.

How will the appearance of the site be softened?

The development includes a landscape planting scheme with new woodland and hedgerow planting around the site boundary. This will strengthen screening year-on-year, further reducing visibility.

All main structures are designed in neutral, recessive colours to blend into the surrounding agricultural landscape.

Will the landscape character of the area be harmed?

The site sits within the Braydon Wooded Plateau landscape character area, which already contains agricultural buildings and waste facilities. The LVIA concludes that the new facility will be in keeping with this working rural landscape and will not cause significant harm to local character or to designated landscapes.

Noise

Will the AD plant be noisy for neighbours?

A detailed noise assessment was carried out using the nearest homes as reference points. The study shows that all predicted noise levels are well within the national planning limits set by BS 4142 and BS 8233.

In practice, this means the site will not raise background noise levels in a noticeable way for residents .

What about noise from HGVs and machinery?

Vehicle deliveries are limited to daytime hours only (07:00–19:00 weekdays, 07:00–15:00 Saturdays). There are no night-time HGV movements.

All key plant and machinery will be housed in acoustically insulated buildings, with equipment like blowers and fans fitted with silencers. This keeps operational noise below guideline levels at the site boundary and at nearby homes .

Will construction work be noisy?

Construction will be short-term (12–18 months) and managed under a Construction Environmental Management Plan.

Hours of work are restricted (no noisy activities at night or on Sundays), and contractors will use best-practice measures such as screening, modern equipment, and controlled working hours to minimise impacts .

What are the results of the noise study?

At the closest home (about 300m away), predicted noise from the facility is below background levels at night and only slightly above background during the day. Even then, it is assessed as having a “low” to “negligible” impact.

This means residents should not experience any significant change to the noise environment .

How will you make sure noise stays under control once it’s built?

The facility will be regulated by the Environment Agency permit, which sets strict noise conditions.

If needed, additional mitigation (such as secondary insulation or plant adjustments) can be required.

Air Quality & Odour

Will the plant cause bad smells in the local area?

A full Odour Impact Assessment has been carried out. It shows that predicted odour levels at the nearest homes are well below the Environment Agency benchmark of 3 ouE/m³ (the level at which most people might detect odour).

All food waste deliveries are tipped inside an enclosed reception building kept under negative air pressure, so doors act like airlocks. Air is then cleaned through biofilters and carbon filters before being released.

In short: odours will be contained, treated, and kept to levels too low to cause nuisance.

What happens if odours escape?

The facility will be operated under an Environment Agency permit, which sets strict odour conditions.

We will also operate a monitoring and complaints procedure, meaning any issue raised by the community is investigated and addressed quickly. Continuous improvements (such as filter replacement or extra controls) can be required if odours ever exceeded permitted levels.

Will the plant affect local air quality?

The Air Quality Assessment modelled emissions from the plant (mainly the biogas engines and traffic).

Results show that all predicted pollutant concentrations (including nitrogen dioxide, PM10, and PM2.5) at the nearest homes, schools, and footpaths are well within national air quality objectives.

In fact, the contribution from the facility is so small it is considered “negligible” to “not significant” by planning standards .

What about HGV emissions?

The additional HGV movements add less than 2% to existing traffic flows on the B4042. Even at this busiest point, the impact on local air quality is assessed as negligible.

Deliveries will use modern, low-emission vehicles and restricted routes, further reducing impacts.

How will you make sure air quality and odour stay controlled?

- Continuous monitoring and strict permit conditions.

- Regular maintenance of odour control systems.

- Filter replacement schedules built into site operations.

We want to hear from you