Soil & Aggregate Recycling

1,200,000 tonnes

of Soil Recycled

Equivalent of 21,000 tonnes

of CO2 Prevented

Eco has been an industry expert in accepting, producing and suppling of topsoil since 1997. During this period Eco has supplied soil to thousands of construction, landscaping and horticultural projects across the UK.

At Eco, we accept over 60,000 tonnes of excavated topsoil each year. Using stringent quality control processes, from reception, through blending (with our PAS:100 compost) and processing to product stockpiling, sampling and testing, Eco ensures the highest standards are met to produce a range of quality, consistent topsoils to a British Standard.

Please get in touch to discuss how Eco can help process your excavated soil to produce reusable products.

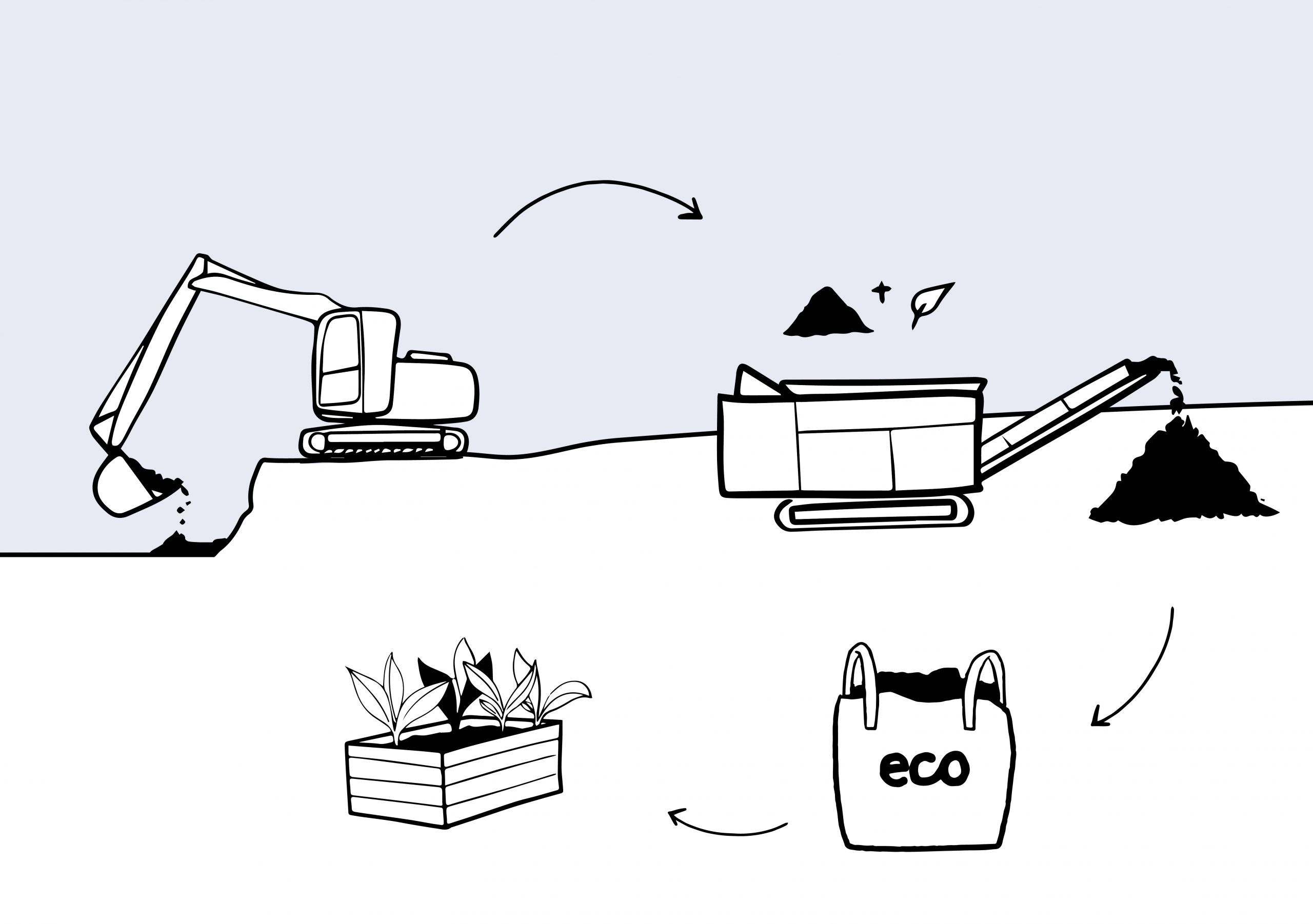

Process steps:

- Soil Excavation: Local construction and landscaping businesses often have excess soil from projects, which needs to be re-homed. This material is delivered to our Parley recycling facility where it is inspected for quality control and categorised.

- Blending and Screening: Soils are blended with our signature compost product, Eco Mix, to create a homogeneous mix before being processed through dedicated screening equipment which size grades the material and removes any contamination.

- Stockpiling & Distribution: The finished Topsoil is then categorised and stockpiled. Stockpiles are then sampled and analysed to ensure that they meet the required size distribution as well as meeting the BS:3882 classification standard for Topsoil. Our Commercial and Logistic Teams then organise delivery to customers in loads between 29 tonnes right through to bulk and even retail bags, for our customers.

Aggregate Processing

Not content with recycling just the local soil supplied to us, Eco have invested in a state-of-the art aggregate washing facility to clean the aggregate fraction from the deposited soil.

The facility, which can process over 75,000 tons a year of recycled aggregate, produces a range of high quality, washed sand and stone tested to comply with standards and supplied to local construction sites across the south cost, through our partners, or collected from our Eco Park by trade customers.