Food Waste Recycling

91,000 MWhs

of Green Electricity Produced

Equivalent of 33,000 houses

Powered for a Year

620,000 tonnes

Food Waste Recycled

Efficient food waste recycling can deliver huge benefits for businesses, the local environment, and long-term sustainability.

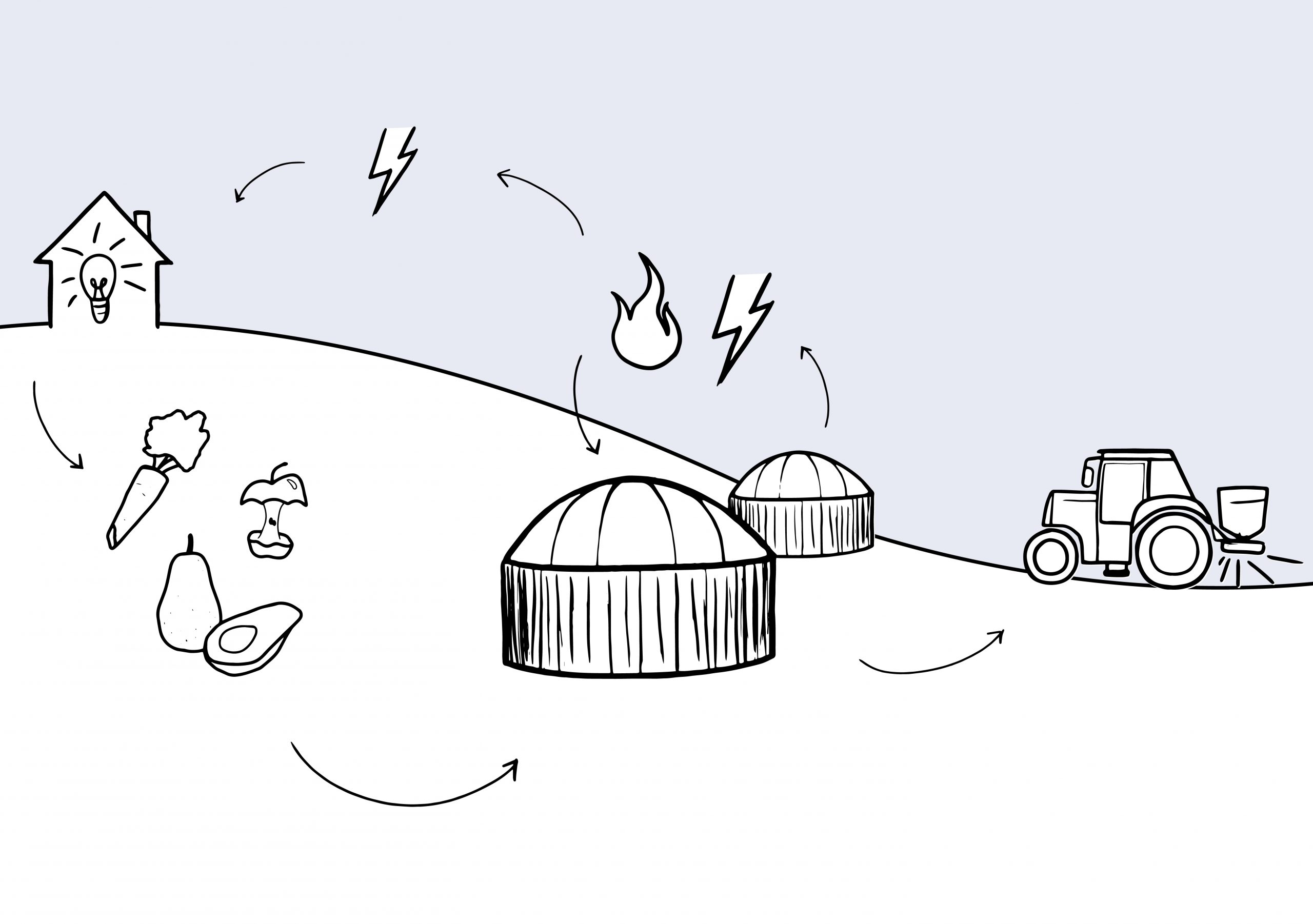

Eco provides collection and treatment solutions for anyone who generates food waste, including commercial, industrial, and household food waste. Supplying our state-of-the-art Anaerobic Digestion facilities which converts this waste into renewable energy and high value fertiliser, closing the circular loop.

Please get in touch to discuss how Eco can help process your food waste to produce green and renewable energy.

Process steps:

- Food Waste Collected – Whether you’re a homeowner, using a kitchen caddy, or business, Eco offers efficient, weekly collections, either directly, or through one of our partnering contractors. The food is delivered directly, either directly or through a transfer station to one of our AD facilities.

- Anaerobic Digestion – Once the food has been delivered, any contamination is removed, and it is processed into a ‘food soup’ before being pumped into the digestors. These large digestors, which contain thousands of tonnes of food soup, act like a cows stomach, to break down the food and convert it into bio-gas. This bio-gas is then filtered to create bio-methane before being used to fuel large Combined Heat & Power (CHP) Engines, or fed directly into the gas network, where it is distributed to heat our homes.

- Bio-Fertiliser – The spent food soup is then pasteurised (at 70ºc for 1 hour) before being supplied to a network of local farmers who use this nutrient rich soil enhancer as a replacement for artificial fertiliser.