Turf is a fantastic way to give your landscaping project the finishing touch that it deserves, without breaking the bank. It’s quick to lay, doesn’t break the bank and gives unparalleled results.

But how is it made? How do Rolawn create their crisp, fine rolls of countryside that we can unfurl in our gardens like a picnic blanket? Continue reading to find out how.

Click here to read about why we’re a Rolawn approved stockist of turf.

Choosing the Correct Grass Species

The growth of a quality turf stock relies on a number of varying factors and the first to consider is the type of grass that is to be grown. Different species of grass will thrive in different climates so establish the optimal species is not only easier to grow but also cheaper. Rolawn’s Madallion Turf uses a superior blend of ryegrass and fescue that offers a perfect mix of properties like wear resistance, year round colour, and shade & drought tolerance.

Preparing The Ground

There are 2 aspects that need to align to create a robust turf: Quality grass and quality soil. Without a well prepared, rich soil for the grass to grow within, it will struggle to establish itself fast enough to be harvested.

Preparation of the ground begins with compost. This compost usually consists of grass clippings and left over turf from previous harvests and this recycles essential nutrients.

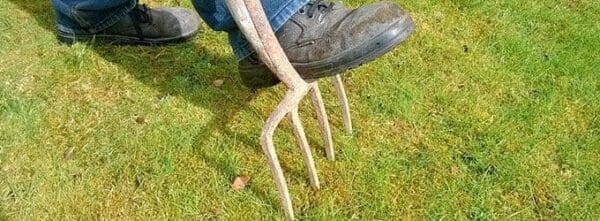

The soil is then aerated using a tractor tool that punctures the ground. These holes allow air, water and nutrients to be absorbed deeper into the soil. It also acts to break up root stalks of grass left over from the last harvest.

Seeding

The soil is already seeded partially from last harvest’s perennial ryegrass leftovers. It’s then topped up with a seed mix that includes fescue grass seeds to create the luscious blend in Rolawn’s famous medallion turf.

The seeds are spread evenly via tractor, using a machine that throws the seeds evenly across the freshly aerated soil.

Watering

Within a few weeks the grass begins to show signs of life and requires steady watering to ensure that the seedlings do not dry out.

In warm climates, constantly rotating watering platforms (central pivot irrigation systems) keep the ground moist to establish the turf’s root system in the upper soil, known as sward.

Fertiliser

Fertilising the grass has 2 key benefits to the turf that can be harvested. The fertiliser gives the grass essential minerals and food it needs to flourish, this allows it to thrive both before harvest and when it’s laid. The fertiliser also gives the turf everything it needs to survive transit whilst it’s no longer connected to the planet.

The fertiliser will contain a cocktail of minerals that encourage the turf to thrive. The fertiliser’s Nitrogen, phosphorus, potassium and iron give everything essential for plant proteins, DNA and chlorophyll production and operation. The zinc in the cocktail plays a key part in many of grass’s enzymes, proteins and hormone production whilst Magnesium is used as a building block in the plant’s photosynthesis process.

Mowing

The soon-to-be turf is mown 3-4 times a week. Only a small amount of grass is cut off per session, around ¼ of the grass’s total growth. This is so that the grass remains focussed on establishing a strong root structure, rather than repairing the grass’s length.

The grass clippings are left on the turf, returning even more nutrients to the ground.

It takes up to 18 months for the grass to establish its root system and be ready for harvest.

Harvest

18 months after seeding, the turf is ready for harvest.

Harvesting the turf is done with a large tractor tool that automatically flattens, cuts and rolls the grass into turf rolls.

A blade slides beneath the grass in a sawing motion, whilst 2 blades at either side cut the strip at the sides and move it onto the conveyor belt. A tool on the conveyor belt rolls the turf into handy bundles and lines them up onto a pallet for delivery.

Now, the turf is ready to be dispatched and laid in a well prepared soil.